The transformation direction of China's textile industry is undoubtedly through technological progress and the improvement of labor quality to achieve the transformation and upgrading. Enterprises increase efficiency, catch or exceed the increase in production costs by improving production efficiency, which is the meaning of the transformation and upgrading. "Machine substitution" is one of a way.

China's textile economy has undergone the advantages of rapid development, cheap human resources and rich natural resources, non-woven machinery and equipment for 30 years. Manufacturing industry is facing the problem of transformation and upgrading as one of the main body of economic development. The disappearance of the demographic dividend, the increase of production costs, the new generation of migrant workers’ awareness of paying more attention to their own rights, China's textile industry development is facing reform.

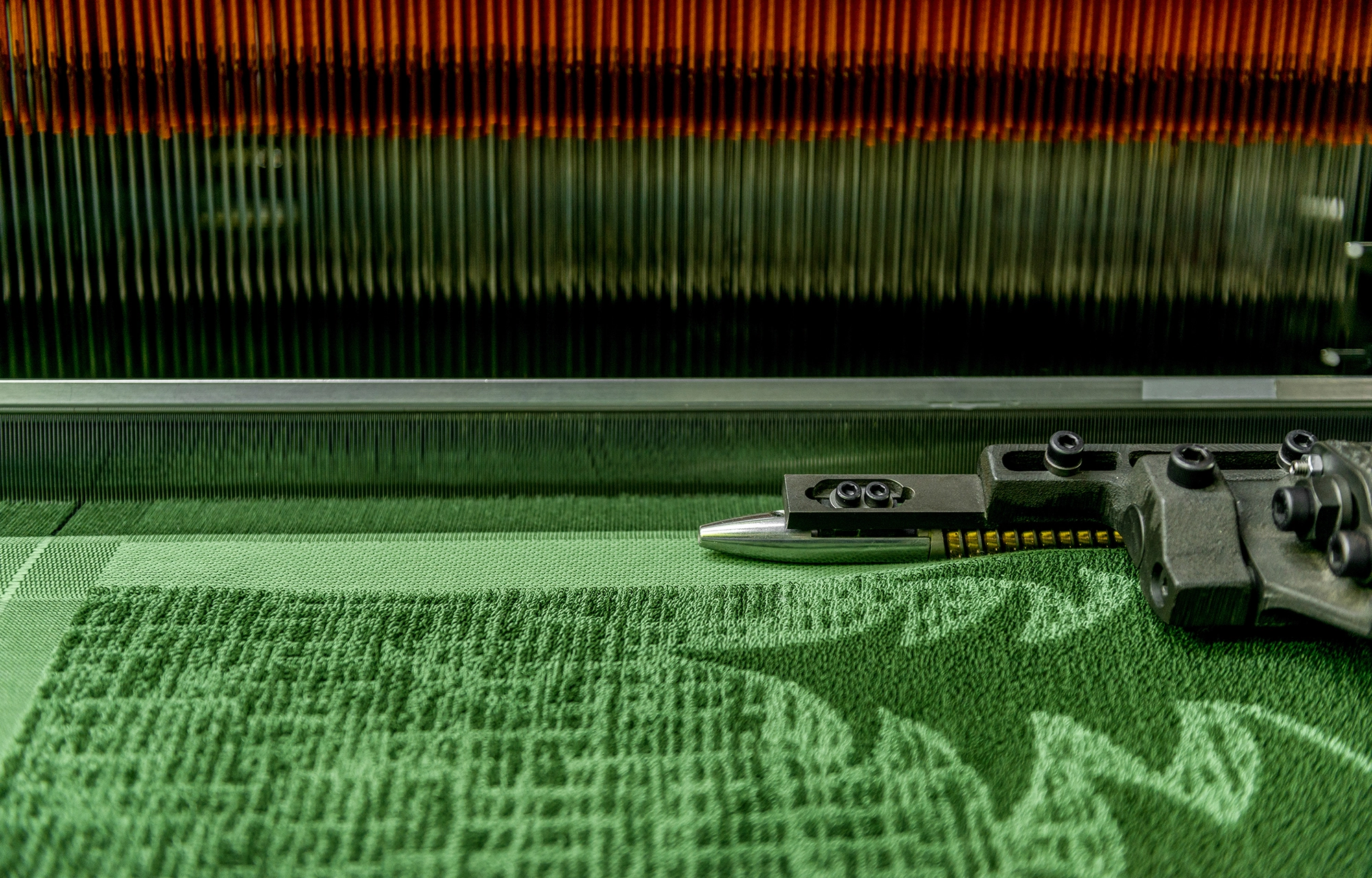

Although China has become a major textile machinery manufacturing, but the level of textile machinery manufacturing is not high enough. As a result, enterprises must accelerate the transformation and improve technical performance. Low-grade products technology content, low value-added, high labor costs, low production efficiency is not in line with the current market requirements, fails to adapt to the future development of the enterprise. So textile machinery product transformation and upgrading is the general trend.

The transformation direction of China's textile industry is undoubtedly through technological progress and the improvement of labor quality to achieve the transformation and upgrading. Enterprises increase efficiency, catch or exceed the increase in production costs by improving production efficiency, which is the meaning of the transformation and upgrading. "Machine substitution" is one of a way.

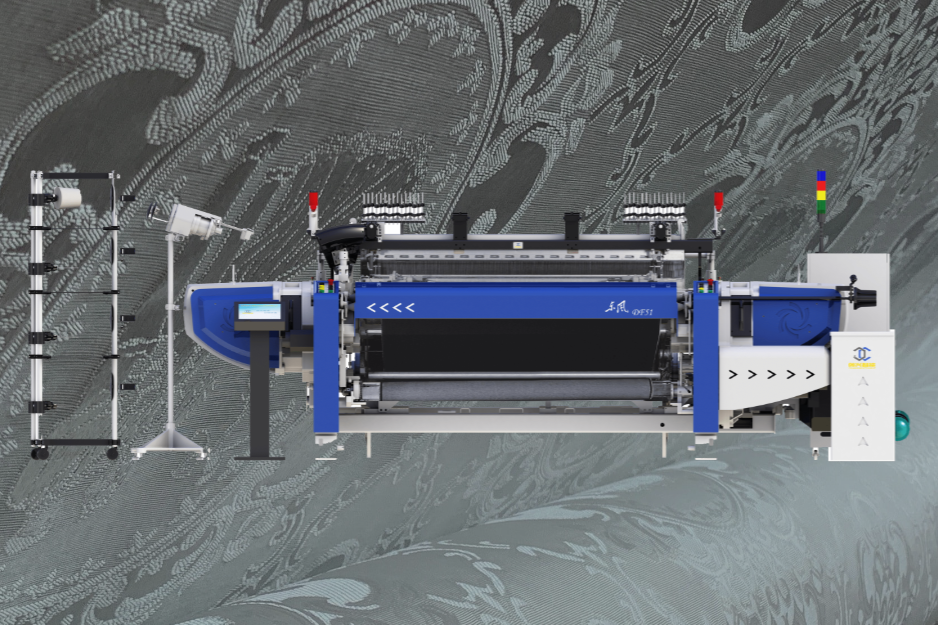

The exports of textile industry said that textile enterprises can reduce labor, improve efficiency by using high-speed, intelligent and high-capacity textile machinery equipment. Because of the shortage of global cotton and other raw materials at present, high-grade textile machinery and equipment can make full use of fiber, improve product value-added. In the next 5-10 years, this trend of demand will be more pronounced.

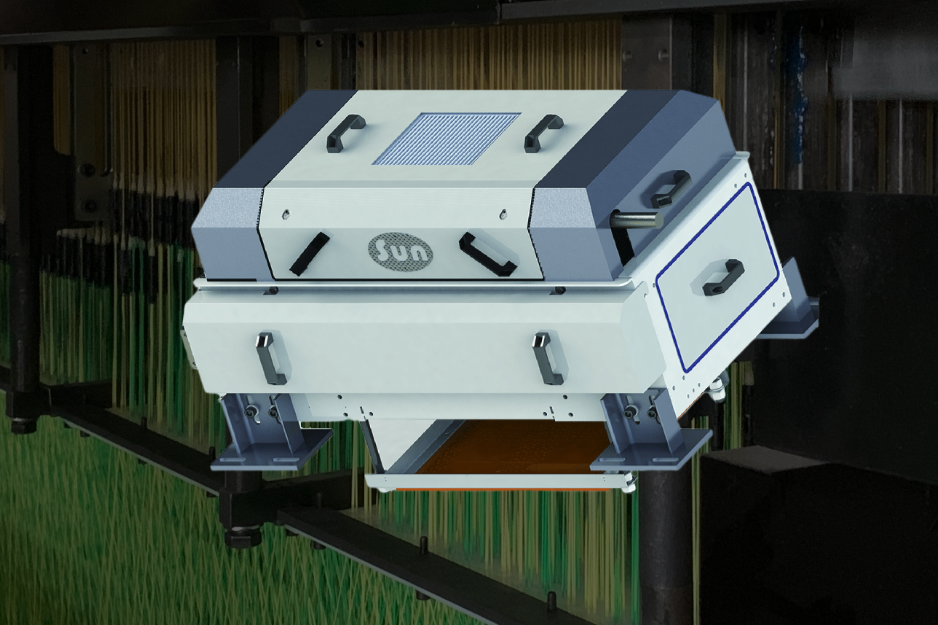

Substitution of textile machinery machine is the inevitable trend of industry development

Recently, a upsurge of "machine substitution" of smart equipment replacing labor input, is sweeping Zhejiang, Guangdong, Jiangsu and other manufacturing areas, causing concern. It is reported that only in Jiaxing city, Zhejiang this year there will be 800 enterprises implement the "Machine substitution", 800 technical renovation projects and a reducement of 80,000 employees; Guangzhou Guangdong had planned not long ago, which intends to to let industrial robots widely used in the city more than 80% of the manufacturing enterprises within a few years.

Shaoxing Jinhui Textile production capacity of 30 million polyester fabric technical renovation project has on line one and a half months ago. The new acquisition of 260 new water jet looms, 9 sets of vehicles, 26 wire cars, 260 fold twisting machines has all put into use, which is expected to increase sales of 200 million yuan, a net profit of 5%.

Worries with the benefits of textile machinery substitution

1.Use whose machine?

China has a comparative advantage in the production of general consumer goods, but the advantages of equipment manufacturing are not obvious. At present, foreign machines are mainly used in the machine substitution. The root cause of the market disparity lies in the gap between the technological level of our equipment manufacturing industry.

2.Who is being replaced and who can operate the machine?

The machine replaces the operators who sell their muscle, but it does not mean that no one is needed. A skilled worker is still the person who knows how to operate the machine. It will be difficult to achieve a real transition and upgrade if the lack of skilled workers to operate and repair these advanced machines.

3.Where do the replaced people go?

The traditional manual workers will be surplus and manufacturing will be structural unemployment as a result of machine substitution. Therefore, in the process of machine substitution, we should make an overall consider of the industrial upgrading and expanding employment to minimize the pains and increase the employment channels. Both manufacturing and workers need to realize their own transformation and upgrade.

Apr,06,2025

Boost Textile Efficiency with the Automatic Warp Tying Machine- Principle, Functions & Industry Value

Mar,02,2025

Common Causes of Weft Breakage on Rapier Looms and General Solutions

Jan,01,2025

FAQs about Sinotextile Carbon Fiber Weaving Line

English

English  한국어

한국어  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Malay

Malay  हिंदी

हिंदी  Indonesia

Indonesia  বাঙালি

বাঙালি  اردو

اردو