A Brief Introduction to Weaving Machine Heald Frame

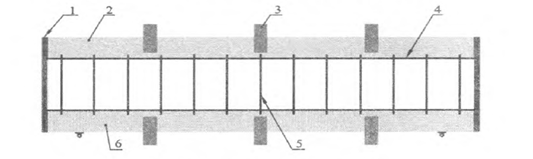

Heald frame is also called heddle frame or harness frame. It is an important part of weaving loom. The structure of heald frame is composed of upper cross beam, lower cross beam, two side stays, heddle rod, rod holder and guide board.

1-side stay, 2-upper cross beam, 3-guide board

4-heddle rod, 5-heddle, 6-lower cross beam

The Function & Classification of Heald Frame

After heddle frames are installed on the loom, warp yarns will be inserted in the eyes of weaving heddles and move vertically up and down. The movement of heddle frames and heddles creates warp yarn shedding for the weft yarn to go across. Weft yarn enters repeatedly through the shedding of warp yarns and finally form the woven fabric.

According to the application in different types weaving machine, heald frames are classified into rapier loom heald frame, air jet loom heald frame, water jet loom heald frame and projectile loom heald frame.

According to material, heald frames can be made from al-alloy, steel, carbon fiber, magnesium alloy and etc. Heald frames made by carbon fiber embody excellent rigidity and lightweight, 25% less in weight compared with al-alloy heald frame, hence reducing energy consumption, lowering the abrasion on loom driving system and other accessories. The overall rigidity of carbon fiber heald frame is 25% higher than made by al-alloy, providing enhanced stability of heddle carrying rod, sequentially prolonging the working life of weaving heddles.

According to weaving heddle (or heald wire), heald frames also have different types such as J type, C type, O type and special type.

According to the attaching method of heddle rod, heald frame can be classified as conjoined type and split type. In conjoined type heald frame, the heddle rod is fixed directly to the upper and lower beam; in split type heald frame, the heddle rod is fixed to beam through bracket.

The Criteria & Technical Requirements of Heald Frame

In order

to carry out a smooth and stable weaving process, heald frame should meet

following criteria,

(1) A firm structure with relevant accessories to cooperate well with loom.

(2) Good mechanical performance, with certain strength and stiffness.

(3) Smooth and flat surface, and accurate dimension to fit on loom.

(4) Heald frame must be well fitted with heddles.

While manufacturing heald frames, the following technical requirements should be strictly implemented,

(1) Planeness should be equal or less than 1mm.

(2) Perpendicularity, i.e. the interval between side stay and standard square should be equal or less than 1mm.

(3) Driving hook should be firmly attached to cross beam or side stay, avoid from loosening or falling off.

(4) Connection of heald frame should be firm and tight, to ensure stable performance under the tensions in high speed movement.

(5) The cross beams should be straight and firm, its strength of extension equal or greater than 240MPa. Sectional dimension of cross beam should be decided according to loom and fabric specification, to ensure a sufficient strength.

The Structure & Choose of Heald Frame

(1) The basic dimensions for heald frame

The distance between heddle rod is decided by healdloop; working width of the heald frame equals working width of heddles rod; total width of heald frame is determined by weaving loom structure.

(2) Determination of heddle distance

|

Heddle Spec |

Closed Type Steel Heddle (O Type) |

Open Type Steel Heddle (J Type) |

||||||

|

Healdloop Distance |

280 |

302 |

330 |

380 |

280 |

306 |

331 |

382 |

|

Heddle Distance |

278 |

300 |

328 |

378 |

277 |

300 |

328 |

379 |

(3) The choose of heald frame guide board

There are two types of heald frame guide, fixed and flexible. Fixed heald frame guide is attached to cross beam by adhesive; while flexible heald frame guide is attached without adhesive and hence can make adjustment according to requested dimension.

Maintenance & Management of Heald Frame

The following points should be notice in the maintenance of heald frames

(1) Handle with care to avoid collision.

(2) Routine cleaning to remove sundries on the harness frame.

(3) After finish the mounting of steel heddles, the side stays should be carefully installed back, screws should be tightened to ensure side stays are firmly assembled.

(4) The storage of heald frames must be dry, clean and away from greasy dirt.

(5) Take routine inspection on the heald frames and relative parts to see whether they are loose, deformed or worn out, and give supplement or repair.

(6) Heddle rod should be waxed frequently to maintain lubrication and prevent rust.

Management of harness frame mainly consists of incoming inspection and turnover management. The new heald frames arrived plant should be checked according to below listed items, by random inspection or full inspection,

(1) Whether the assembly of harness frame is firm and secure.

(2) Whether the dimension of harness frame and accessories is correct.

(3) Check whether the four corners are right angle by diagonal method.

(4) Check the planeness of harness frame on horizontal inspection plate

(5) Check whether the appearance of heald frame is flat, smooth, without burr or crack.

And in turnover management, it is requested that,

(1) Heald frames to be put in storage, classified and stacked in order, the inventory quantity should be counted.

(2) The storage should have distortion protection, moisture protection and rust prevention.

(3) Periodical inspection should be conducted in order to find problem and solve in early time.

(4) Explicate stipulations should be implemented for harness frame working life and abrasion life, maintenance and scrap to be done accordingly.

(5) Make new harness frame purchase schedule according to current service condition and inventory condition.

English

English  한국어

한국어  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Malay

Malay  हिंदी

हिंदी  Indonesia

Indonesia  বাঙালি

বাঙালি  اردو

اردو