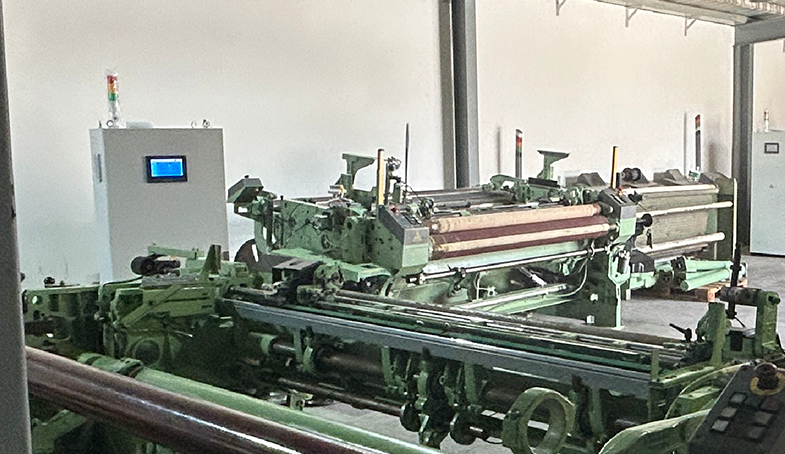

With over 12 years of dedicated research and development in rapier loom control systems, Sinotextile offers high-performance, intelligent solutions for the textile industry. Our advanced rapier loom electrical control system integrates key functions such as electronic let-off, electronic take-up, electronic weft selection, electronic jacquard control, and automatic weft tension adjustment. It provides real-time monitoring, self-diagnosis, and remote network management, significantly improving weaving efficiency and fabric quality.

The Sinotextile Rapier Loom Control System features a 32-bit industrial-grade processor at its core, paired with a 7-inch color touchscreen and an intuitive human-machine interface, ensuring ease of operation. It is designed to upgrade and optimize both domestic and imported looms, including:

1.Various FAST loom models from Smit/Nuovo Pignone Company, as well as China Textile Xinlong machine models.

2.Sulzer’s G6100, G6200, G6300 models and their relevant towel loom series.

3.Sulzer projectile looms, including PU, P7100, P7150, P7200, and P7300 models.

4.Somet’s SM92, SM93, THEMA11, THEMA11E, THEMA SUPER EXCEL, and ALPHA series models.

5.Picanol’s GTM, GTX, GTX-AS, GAMMA, and Optimax models from Belgium.

6.GTN, GTV, HTV, HTVS, PTV, PTS, P1, and P2 models from Germany.

7.Vamatex and Itema’s P401, P1001, P1151ES, K88, R880, and LEONARDO models.

8. Even the very old models like Saurer S400 rigid rapier loom.

Upgrade Your Rapier Loom Today

The Sinotextile Rapier Loom Control System enhances productivity, reduces maintenance costs, and enables intelligent weaving. Contact us now for a customized solution!

Universal Type Rapier Loom Control System

The popular rapier loom control system leverages over a decade of rapier electronic control design experience. It has a rich interface and is compatible with most rapier looms available on the market. It is particularly suitable for models that require high cost-performance and reliability. The system allows for flexible addition or removal of external modules via a standard expansion interface to provide a comprehensive solution.

Features

•Real-time tension curve display

•Space-saving, low-cost, and easy maintenance

•High-speed main frequency with an embedded real-time operating system

•Integrated design: The main controller, take-up control, and braking are all on a single motherboard, simplifying interface and layout while reducing costs.

•Optimized electrical box structure: Significantly reduces internal heat generation, eliminating the need for ventilation holes in the cabinet.

•Upgraded and optimized control principles: Various flexible accessory options improve cost-effectiveness.

•Networked centralized unified control: Enables remote monitoring, diagnostics, and upgrades via the internet.

•Rich interface: Up to 200 input and output interfaces.

•Provides loom status information, fault, and operation logs.

•Powerful on-screen pattern editing function with accompanying computer pattern editing software.

•Customizable for special models: Such as terry looms and carpet looms.

•Advanced human-machine interaction system:

•Loom status monitoring

•Customizable display title content

•Backup and transfer of loom parameters

•One-click upgrade: Synchronizes updates for both the touchscreen and motherboard program for easy operation.

Technical Specifications

Item | Specification |

Loom Models | Towel loom, carpet loom, FAST, G6300, K88, GTM, GTX, GAMMA98, SM93, terry cutting loom, etc. |

Shedding System | Dobby: Supports up to 20 heald frames, max 50,000 dobby pattern lines. Jacquard: 12 colors. |

Main Motor | Supports max 800rpm, adjustable speed weaving (only for models with a main motor controller). |

Human-Machine Interface | 7-inch/10-inch/15-inch color touchscreen. |

Warping/Take-up | Various configurations: single warp single take-up, double warp single take-up, 2 warp 1 take-up, 4 warp 1 take-up, etc. Multiple servo motor specifications available. |

Tension Detection | Displacement proximity switch, weighing sensor, encoder (absolute/incremental). |

Weft Selection | Mechanical, electromagnetic, linear motor, stepper motor. Supports mixed weft function. |

Protection | Fully enclosed cabinet preventing foreign object intrusion and maintenance-free. Optional Level III lightning protection and power detection module. |

Statistics | 7-day statistical data; networked version supports up to 6 months of data review. |

Pile Function | Servo motor-driven pile shaft, infinitely adjustable loop height. |

Networking Function | Optional networking module, supports RS485 and Ethernet interfaces. |

Optional Configurations | Electronic selvage, electronic weft scissors, electronic waste-edge scissors, hot cutting knife, thermal ironing plate, safety light curtain, laser warp break detection, customized take-up motor flanges. |

Thank You for Your Attention On SINO TEXTILE !

Related Products

Latest News & Blog

English

English  한국어

한국어  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Malay

Malay  हिंदी

हिंदी  Indonesia

Indonesia  বাঙালি

বাঙালি  اردو

اردو