The Sinotextile Intelligent Water-Jet Weaving Machine Electrical Control System is a cutting-edge solution that integrates advanced electrical control and weaving processes into one compact, high-performance package. Designed for high-speed water-jet weaving machines, it not only boosts efficiency but also significantly enhances fabric quality.

Key Features

High-Speed Precision Control:

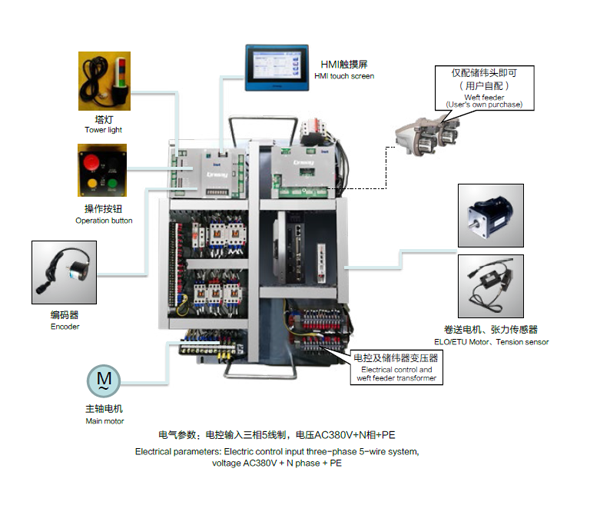

Equipped with a 32-bit CPU and a 7-inch color touchscreen, the system delivers rapid computations and precise control while offering an intuitive user interface.

Integrated Process Technology:

Seamlessly combines electronic warp feeding, winding, and pattern control.

Eliminates common fabric defects such as startup marks, slack, and tension variations through automatic compensation and real-time tension adjustments.

Advanced Servo Drive System:

Utilizes Invt’s high-precision SL212 two-axis AC servo system for both winding and warp feeding, reducing mechanical complexity and ensuring smooth, energy-efficient operations.

Flexible Weaving Capabilities:

Supports variable machine speeds and up to eight different weft densities without the need for gear changes, making it adaptable to various fabric designs and yarn types.

Offers an ultra-start function for high-torque, low-speed jogging, ideal for precise startup conditions.

Robust and Reliable Design:

Eliminates traditional components such as brake discs, belt pulleys, and AC contactors, reducing maintenance needs and minimizing risks of mechanical failure.

Maintains stable machine operation even under fluctuating power conditions thanks to a high-speed, all-servo control architecture.

Enhanced Weft Detection:

Incorporates both photoelectric and fiber optic sensors with an intelligent algorithm to significantly improve detection accuracy.

System Benefits

Improved Product Quality:

The integrated algorithms for warp feeding and winding ensure constant tension, reducing defects and enhancing the overall fabric finish.

Elimination of Common Weaving Issues:

By preventing parking marks and slack, the system supports a flawless start-up process and ensures consistent fabric quality throughout production.

Energy Efficiency and Low Maintenance:

The compact, servo-driven design not only reduces energy consumption but also minimizes maintenance downtime, ensuring a long service life and reduced operational costs.

Wide Compatibility:

Designed as a turnkey solution, it can seamlessly replace various foreign water-jet machine models, including those from leading brands like Jin Tian Jum, making it ideal for upgrading second-hand equipment.

Sinotextile Water-Jet Weaving Machine Electrical Control System is also a perfect replacement of old water jet looms panels like Tsudakoma, Nissan and etc. The performace has been acknowledged by the China domestic and oversea markets.

Thank You for Your Attention On SINO TEXTILE !

Latest News & Blog

English

English  한국어

한국어  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Malay

Malay  हिंदी

हिंदी  Indonesia

Indonesia  বাঙালি

বাঙালি  اردو

اردو