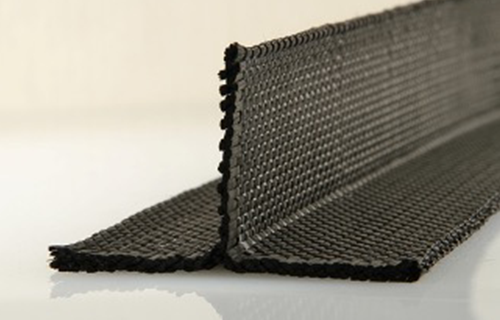

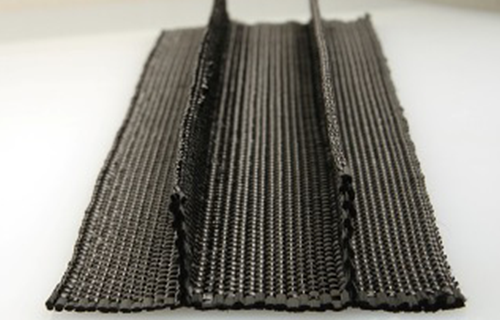

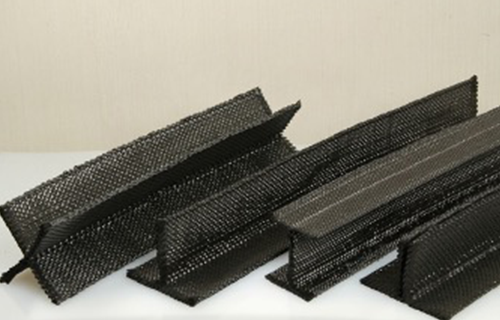

Sinotextile also offers 3D weaving solutions for advanced materials such as carbon fiber, Kevlar, fiberglass, ceramic fiber, and basalt fiber, among others. The 3D weaving loom can create structures like interlayer orthogonal, angle interlock, and various other multilayer structures.

Reduces fiber twisting and turning during the weaving process.

Compact equipment takes up less space, making handling, installation, commissioning, and maintenance more convenient.

Mature and reliable, with all related technologies having been validated.

Let-off:customized creel with longitudinal unwinding. Damping adjustable, yarn spools do not interfere with each other, maintaining the independence of each warp yarn.

Tension:adjustable swing arm with spring mechanism, tension adjustable.

Yarn seperation:reed frame with line separation guide rods, ensuring that yarns do not affect each other during production.

Heald lifting:cylinder lift harness, combined with electric control programming, specially designed multi-eye harness threads, more suitable for carbon fiber, glass fiber, etc.

Weft insertion:driven by a servo motor, providing smoother operation. Mechanical edge twisting.

Beat-up:cylinder-driven parallel weft beating, maintaining a certain beating force, with adjustable beating time.

Take-up:driven by a servo motor, with clamping blocks. Motion quantity controlled precisely, weft density accurate, parallel winding, fabric remains unbent, and does not damage fabric properties.

Electrical control and software:touchscreen interface, intuitive pattern input, fabric design software has copyright for computer software.

Project Indicators | Performance Requirements |

Fabric Width | customized |

Warp Density | 2~8wefts/cm |

Weft Density | 2~6wefts/cm |

Fiber Type | Carbon Fiber 1~24k / Other Coarse Fibers |

Fabric Length | customized |

Fabric Structure | Interlayer Orthogonal, Angle Interlock, and Various Other Structures. |

Number of Heddles | Up to 20 |

Number of Layers | multilayer |

Weft Insertion Efficiency | >20 wefts/min |

Equipment Dimensions | Length Approx. 13000mm / Width 4500mm / Height 2500mm

|

Creel | customized |

Power Supply | 220V,16A/220V,10A |

Air Pressure | 0.3~0.8Mpa |

Thank You for Your Attention On SINO TEXTILE !

Related Products

Latest News & Blog

English

English  한국어

한국어  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Malay

Malay  हिंदी

हिंदी  Indonesia

Indonesia  বাঙালি

বাঙালি  اردو

اردو