As an integrated textile parts manufacturer, we are able to supply a complete range of original and non-original weaving loom parts. Our range includes weft feeder, weft sensor, electronic weft selector, drop wire, leno selvage device, guide slide, heald wire, warp stop motion, tuck in device, cutter & blade, rapier gripper, drive wheel, rapier tape, guide hook, ring temple and other common replacement parts.

We also provide weaving loom parts for Picanol looms, Vamatex looms, Sulzer looms, Dornier looms, Nuvo Pignone looms and etc. These loom parts are manufactured strictly according to the dimensions and requirements of the original parts, and with first-class raw materials. Therefore the parts provided by us have the same quality and performance with the original ones.

The possession of advanced facility, high-efficient management system, plenty of professional technicians, strict quality control system has contributed to the continuous and rapid development of our company. Our textile spares are sold to every corner of the world and get universal recognition from the clients. We will continue the research and development on various kinds of textile parts and accessories to meet the needs from different customers.

Heald frame is an important in weaving machine. It opens shed for weft yarn to come through and hence form different weaving patterns.

View More

We have more than 20 years experience in research, development and distribution of weaving loom reeds.

View More

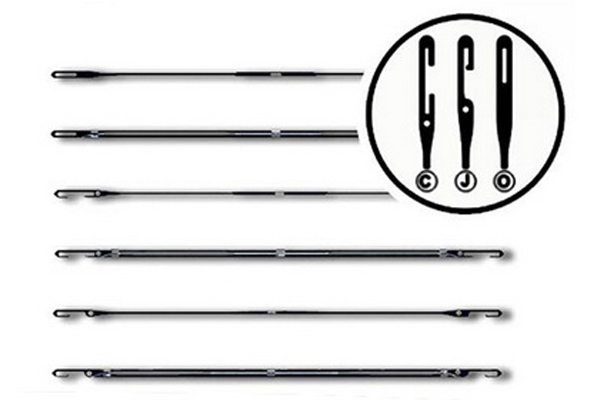

Heald wires are used to lead the warp yarns to move in lifting motion, forming a weaving shed for weft yarns to be brought in.

View More

We provide complete range of weft cutter, selvedge cutter, blades, cutter assembly covering various brands including SOMET, PICANOL, VAMATEX, DONIER, TOYOTA, and etc.

View More

We manufacture supply top quality electromagnetic clutches and brakes that are in applied in shuttleless weaving machines.

View More

We are supplying electronic leno selvage device and leno healds to be installed on various weaving looms.

View More

Sino textile range of weft accumulator caters diverse requirements of industrial applications, suitable for rapier looms, water jet looms and air jet looms.

View More

Ring temples are used to give horizontal tension to the weaving fabric so that the weaving fabric will not shrink.

View More

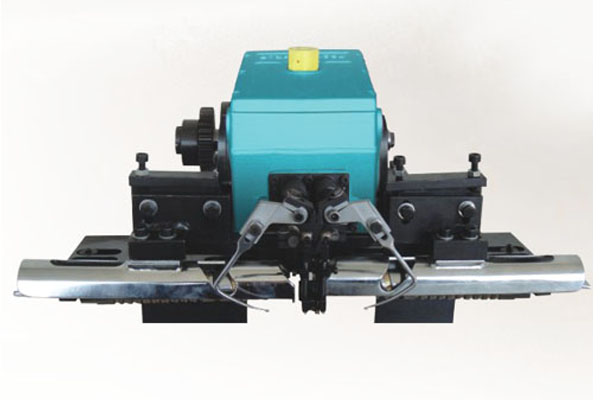

Sino textile have tucking devices for China low speed rapier looms, high speed rapier looms, air jet looms and etc.

View More

Our Customers can purchase from us various specifications of warp stop motions used in shuttle-less looms.

View More

We have abundant experience and knowledge in delivering a wide range of guide rail to our customers.

View More

We are able to supply abundant circuit panel for weaving looms, with first class quality and maximum lifespan.

View More

Weft Sensor is used for weft detection on weaving looms. During the weft insertion process the weft yarn is drawn from the thread guide of the sensor.

View More

Our electronic weft selector can be applied in high speed rapier loom with speed above 400r/min.

View More

With over 10 years of experience in manufacturing motor, step motor and encoder, we are now supplying the highest quality products to be fitted on textile weaving machines.

View More

We offer a wide series of electronic parts for textile weaving machines like approach switch, membrane switch, proximity switch, bush button, load sensor, tension sensor, load cell and etc.

View More

The electromagnet and coil supplied by us are designed, manufactured and controlled strictly according to ISO standard.

View More

Weft feeler is to control the weaving machine to stop after weft breakage. Our automatic weft feeler has the advantages of simple circuit, reliable performance, excellent security and lower cost.

View More

We have been researching, developing and distributing membrance switch and touch screen panels for more than 10 years.

View More

Richard SWIFT

Q: What will be the difference of the profiled reed used in air jet loom requiring two nozzles and more than two nozzles?

Q: What are the main types of selvedges and how they are formed?

Q: How to choose qualified drop wire for weaving?

Q: How to choose qualified heald frame for weaving?